Biological & Organic Waste Treatment Products

B.O.G. ProcessTM

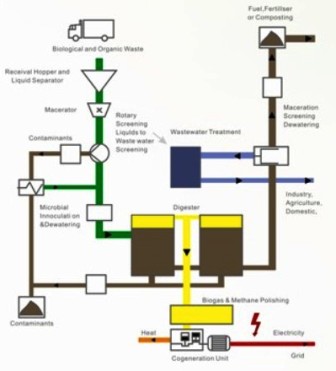

B.O.G. ProcessTM -- The Tailored Integration of Waste Water & Liquid Treatment and Biological & Orgacis Waste treatment Technologies

Main Technologies

Accelerated transformation of biological & organic waste materials anaerobically or aerobically in a single stage fermentation vessel.

Single vessel, high density, high solids processing using a combination of physical and microbial technologies.

Decontamination and molecular breakdown of certain non-biological materials as required.

Integration with B.O.G. Water Treatment Products -- aearation, filtration, purification and recycling if required.

Description

The B.O.G. ProcessTM Breakdown and transformation of organic substances into a microbial mass. High molecular weight substances consumed to generate methane, carbon dioxide water and digestate -- anaerobic process.

High density solids processing to reduce tank size requirements and capital costs.

Accelerated digestion via enhanced microbe/substrate interface.

Enhanced biogas production.

Digestate composted to treat cellulose and ligninatious material in a thermophilic compost process--aerobic process.

Integrates other waste streams including other landfill compost, green waste (trees and straw etc.) leachate water and other effluent streams if required.

The BOG ProcessTM does not redefine how aerobic and anaerobic digestion of biological materials occur. The science is well known and understood. We simply create conditions whereby the process is accelerated considerably using less energy than current processes.

The B.O.G. ProcessTM has modularised processes to allow it to be tailored to Client specific needs and scale.

Applications are tailored to Client requirements. Waste streams may be treated separately or integrated with other wastes to enhance energy generation.

Kitchen Waste -- multi stage treatment -- separate gutter oil, digest organic matter, harvest biogas for electricity and heat, compost residual cellulose and ligninatious materials and treat residual liquids to required standards.

Fats Oils & Grease -- Gutter Oils -- collect separately, treat and transform to energy

Waste Water Treatment Plant Sludge -- multi stage treatment decontaminate certain contaminants, digest sludge aerobically or anaerobically for energy and heat, recover water and use digestate as a fuel or fertiliser

Primary sewage pond

Landfill -- multi stage treatment -- Leachate, and Organic Waste

Poultry Abattoir waste -- removals of fats oils and grease

Milk Processing, dairies -- filtration, effluent, water, energy recovery

Intensive Animal Feeding -- Pigs, Chickens, Ducks, Aquaculture, Dairies, Feedlots

Energy Cost Reductions up to 100%

Transformation of disposal costs into income

Reduced Capital Costs, smaller plants for better outcomes

Reduced Operating Costs -- less energy cost required to operate

Simple systems -- easy to operate

Decontamination of certain contaminants over time

Environmental compliance

Significant BOD and COD reductions

Recovery of clean water, energy and dry or semi dry solids

Enhanced health -- pathogen and vector attraction minimised

Reduced greenhouse gas emissions

Creating carbon credits

Odour reductions by >80% when measured against landfill disposal

Sludge volume for transport and disposal reduced by up to 85%

Requirement for landfill, waterways, incineration and wet agricultural disposal minimised or eliminated

Next Page: B.O.G. Lagoon and Vessel Aerator

2007-2024 Bio Organics Group (Hong Kong) Ltd ALL RIGHTS RESERVED ACN 98123739088

2007-2024 Bio Organics Group (Hong Kong) Ltd ALL RIGHTS RESERVED ACN 98123739088