B.O.G. Commercial & Industrial Filtration

The CrossFlowMF1.0® Operating System and its Advantages

Utilises a unique, patented, vortex bed, stabiliser which maintains flat bed filtration with high surface turbulence. This ensures no bio-fouling can be seeded whilst holding filtered contamination in suspension above the media bed. This gives lower pressure drops, longer filtration cycles and shorter backwash making direct saving on operating costs.

Main Advantages

Industries

- Automotive

- Brewing & Distilling

- Chemical

- Commercial Buildings

- Shopping Malls

- Hotels & Leisure

- Paper & Textiles

- Food & Beverage

- Pharmaceutical

- Plastic Extrusions & Mouldings

- Power Generation

- Steel & Metals

Principal Applications

- Potable Water

- Effluent Treatment

- Municipal waste water

- Industrial waste water

- Process Water

- Environmental Protection

- Reverse Osmosis Protection

- Borehole In-Take

- Canal Water Filtration

- River Water In-Take

- Sea Water In-Take

- Heating/Cooling Systems

- Cooling Tower Enhancement

- Leisure swimming pool and spa HSE protection

- Heat exchanger protection up to 15%-20% energy reduction on HVAC systems

Tangential inlet

With Patented Vortex Stabiliser

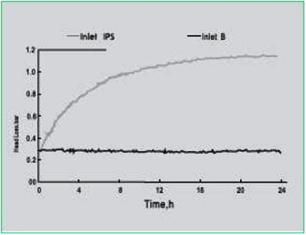

Pressure Drop Comparison Between Conventinal Media Filter and Crossflow

- The patented inlet design gives a media bed which is rotating at all times.

- The bed motion prevents bacteria from becoming established within the media bed - a major problem with Vortisand and PEP.

- The media is continually being refreshed - this is important as we refresh the media ability to "attract" the fine contamination by refreshing its ZETA potential.

- Pressure drop is very low - even at very high flux rates as we are NOT depending on the bed to foul to give fine filtration - this is achieved by the mixing of the media within the inlet chamber

- The rotating bed in combination with the patented "Vortex stabiliser" ensures that the bed is of uniform thickness at all times, there is no possibility of rat holing or channelling - a major failure on media filters.

- The "Advanced Filter media" is based on recycled glass, the treatment process gives the media a ZETA potential charge, which is the opposite charge to that of most contamination.

- The Zeta Potential charge is continually refreshed by the aggressive rotation within the filter combined with that of the Vortex Stabiliser, so it has a far higher dirt loading capacity than conventional filters.

- The media fluidises above the main rotating bed and in doing so interacts with incoming contamination.

- Refer to http://www.crossflowmf.com/ page 7/8 for a demonstration.

- The High Flow rates up to 60 m3/hr /m2 (flux rate per unit) enable this technology to handle much higher flows with much finer filtration.

- Because the high flow rotates the bed the normal progressive pressure build up is postponed as the larger filtered contamination remains rotating within the top section of the vessel (not unlike a cyclone) so has no effect on operating pressure, whilst the finer elements react with the special media, only to become agglomerated into larger particles which on reaching the rotating bed are placed in rotation with the other larger contamination. If the solids load increases the Crossflow AMFTM backwashes more frequently and this is fully automated in response to variable loading of input material, consequently output remains consistent.

- When backwash is activated by pressure drop ( usually 0.5-0.7 barg) the majority of the contamination is in the water volume above the bed, so on backwashing the water volume required is limited to the displacement of this dirty water volume and the vertical fluidisation of the bed to ensure good layer definition and media cleanliness (normally about 20% of water per backwash of a like for like filter)

- This high flux rate makes for a very competitive option especially if the client is wanting to filter below 10 micron level

Next Page: B.O.G. Rotary Screening

2007-2024 Bio Organics Group (Hong Kong) Ltd ALL RIGHTS RESERVED ACN 98123739088

2007-2024 Bio Organics Group (Hong Kong) Ltd ALL RIGHTS RESERVED ACN 98123739088